45 A – 700 A (10 hp – 400 hp)

208 / 230 / 380 / 480 Volts

3Ø DC Package

Control Techniques’ Quantum MP

is a packaged

Mentor MP high performance DC drive providing

reliability, power, and control to increase productivity for

both new machines and applications in which DC

motors are already installed.

The Quantum MP package includes the drive,

fusing, power switching and 115Vac interface making it the

ideal choice for rapid retrofits with regenerative and

non-regenerative modules available to suit your application.

The Quantum MP saves engineering time and

panel space making it ideal for North American customers.

-

Features

Flexible system integration

Quantum MP is a modern packaged DC

drive that has unparalleled flexibility through the

integration of Control Techniques' AC drive control

technology on a DC drive. This means the Quantum MP

inherits system integration flexibility, such as:

-

Two available SM option module

slots for automation control, I/O, feedback

devices and communications

-

SMARTCARD for PLC program and

parameter storage

-

PC tools for easy configuration,

monitoring, and diagnostics

Additional features include:

-

Patented (pending) galvanic

isolation protects control circuits against poor

quality industrial power supplies and high

voltage circuitry

-

Powerful onboard intelligence

fine-tunes the drive’s functionality to the

application and allows the removal of

troublesome analog control circuits

-

Communication options include

EtherNet/IP, Modbus TCP, PROFIBUS DP, and

DeviceNet allowing Quantum MP to be integrated

within any automation system

-

CTSoft, a windows-based software

package, provides an intuitive environment for

configuring the drive's functionality

-

Quantum MP integrates closely

with Control Techniques AC drives using CTNet

drive-to-drive communications

Technology for reliability and performance

Quantum MP takes a step forward in

performance, robustness and reliability:

-

High performance motor control

-

Galvanic isolation (patent

pending) between power and control protects the

control circuits and other equipment connected

to the drive from the high voltages on the power

circuit. This feature is unique on DC drives

-

Protection system against poor

industrial power supplies and lightning strikes

-

Integrated drive and motor

protection

Flexible field control

Internal field controller with

intelligent field weakening means that 90 % of

applications require no additional external

controller

-

Integrated field control on

frame size 1 to 8 A

-

Integrated field control on

frame size 2 to 20 A

-

Flux control for enhanced

open-loop performance

-

External FXMP25 field

control to 25 A

Specifications

-

High-speed semiconductor fusing

for reliable circuit protection

-

115 Vac control interface to

coordinate signals and commands to the drive

-

DC loop contactor (with DB pole

up to 250 hp @ 480 Vac) disconnects the Quantum

MP drive from the motor armature when stop

command is given or in the event of a power

failure

-

DC output fuse on all Regen

models helps avoid nuisance trips

-

Regenerative and

non-regenerative modules available to best match

application needs

-

Multiple fieldbus options

including EtherNet/IP, Modbus TCP, PROFIBUS DP,

and DeviceNet are used to integrate Quantum MP

drives into automation systems

-

Enclosure IP00

Environment

-

Ambient operating temperature:

32 ° to 131 °F (0 ° to 55 °C )

-

Derate current 1.5% per °C from

104 ° to 131 °F (40 ° to 55 °C )

-

Cooling method QMP25-QMP45

natural convection

-

QMP75 and larger forced

convection

-

Humidity 90 % relative humidity

at 122 °F (50 °C)

-

Storage temperature: -40 ° to

131 °F (-40 ° to 55 °C )

-

Altitude: 0 to 9,842 ft (0 to

3,000 m), derate 1 % per 380 ft (100 m) between

3,280 ft (1,000 m) and 9,842 ft ( 3,000 m)

AC supply requirements

-

Supply voltage 208 to 480VAC ±10

%

-

Frequency 48 to 65 Hz

-

Supply fault current 100 kA

-

Drive efficiency 99 %

-

Armature voltage (max.)

non-Regen drives — 1.35 X input VAC; Regen

drives — 1.15 X input VAC

-

Field voltage (max.) 0.9 X input

VAC with 1-phase input

Control

-

Analog input resolution: 16-bit

plus sign, 250 μs (Qty 1), 10-bit plus sign, 250

μs (Qty 2)

-

Speed loop: 250 μs loop update

-

Current loop: 35 μs current

sampling time

-

Feedback methods

-

Encoder (resolution 0.01 %)

-

DC tachometer (resolution 0.1

%); AC tachometer (resolution 1 %) (300 V max.)

-

Armature Voltage (resolution 5 %

)

-

Optional additional incremental

and absolute encoders (Qty 2)

-

Field control current regulated

with flux control

-

QMP25-QMP 8 A

-

QMP350-QMP700 20 A

-

Optional FXMP25 25 A

-

Serial communications: 2- or

4-wire RS422 or RS485, optically-isolated

-

Protocol: ANSI x 3.28-2.54-A4 or

Modbus RTU

-

Baud rate: 300 to 115,200

Protection & diagnostics

-

Control: Galvanic electrical

isolation, 24 Vdc power supply

-

Supply: Loss, under-voltage,

overvoltage, transient suppression,

semiconductor fuses

-

Armature: Open circuit, I2t

overload, instantaneous over current,

semiconductor fuse (Regen only)

-

Field: Loss, over current

-

Motor: Motor over-temp switch or

thermistor over-temperature trips

-

Drive thermal: Heatsink, SCR

junction, control board and option module (s)

-

Current loop loss: Loss of

analog current reference

24 Vdc I/O

-

Digital inputs: 3 x 24 Vdc

-

Digital input/outputs: 3 x 24

Vdc

-

Analog inputs: 1 x 16-bit

differential

-

0-10 V, 2 x 10-bit voltage or mA

-

Analog outputs: 2 x 10 bit

voltage or mA

120 Vac I/O

-

Inputs

-

EMERGENCY STOP

-

STOP

-

RUN

-

JOG

-

FWD/REV

-

RESET

-

Outputs

-

Relays (quantity 2)

Ratings and dimensions

*Current ratings are at 104 °F (40

°C) with 150 % overload for 30 s. (R) indicates

optional order code for 4-quadrant operation.

**These models do not include

dynamic braking contactors.

HP provided for convenience. Always

size drive based on motor Amps.

Applications

Many DC drive applications are for retrofit systems to

improve the performance and prolong the life of existing plants and

machinery. New applications for DC drives include:

-

High Power applications

-

Ski lifts

-

Printing Presses

-

Heavy Moveable Structures

-

Lumber and Paper Milling

-

Dual-turret winding

-

Plastic and Rubber Extrusion

-

Cranes, Hoists, and Cabling

-

Iron, Steel and Glassworks

-

Tilt Vessels, Coilers, Spoolers

-

Metal Fabrication and Wire drawing

-

Winding and unwinding

-

Pulp and Paper processing

-

Metal Rolling and processing

Benefits

-

Powerful onboard intelligence allows the drives

functionality to be finely customized to the application and allows the

removal of troublesome analog control circuits

-

Modular approach to high power drives allows multiple

Quantum MP drives to be connected in parallel or series to economically

achieve the required motor current and voltage rating

-

CTSoft, a windows based software, provides an intuitive

environment for configuring the drives functionality

-

Our knowledge and experience in DC drive systems allows us

to recommend the best solution for your individual circumstances

-

Quantum MP integrates closely with the Control Techniques

AC drives using CTNet, drive-to-drive communications

-

Regenerative and non-regenerative modules available to suit

your application

-

Fieldbus options including; Ethernet, Profibus and

DeviceNet allow Quantum MP to be integrated within an automation system

-

Worldwide expertise and support

In addition to the features of the Mentor MP, the Quantum MP

drive includes:

-

High speed semiconductor fusing

-

115 VAC control interface

-

DC loop contactor (with DB pole up to 250 hp @ 480 VAC)

-

DC output fuse on all Regen models

OPTIONS

A wide range of solution modules are available to allow you to

customize Quantum MP for your application.

-

Keypads and

parameter storage

|

MP-Keypad

MP-Keypad is a multi-lingual,

hot-pluggable, backlit LCD display

for Mentor MP drives |

|

SM-Keypad

SM-Keypad is a high brightness

LED keypad for Unidrive SP (except

frame size 0) and Mentor MP drives |

|

Smartcard

This memory device can be used to

backup parameter sets and PLC

programs and copy them from one

drive to another |

Drive Interface

Units - Communications

|

Operator

Interfaces and HMI

The powerful CTVue HMI (Human

Machine Interface) line and

integrated drivers for Control

Techniques drives make it easy to

integrate HMI with CT drives |

|

CT USB Comms

Cable

The USB Comms cable allows the

drive to connect to a PC for use

with Unidrive M's PC tools* |

-

Automation

and Motion option modules

|

SM-Applications Plus

SM-Applications Plus offers

high performance programmable

logic and motion control

together with high speed I/O and

CTNet, a high speed Fieldbus |

|

SM-Applications Lite V2

User programmable logic and

motion control module for

standalone drive applications or

for when the drive is connected

to a centralized controller via

I/O or Fieldbus |

|

SM-Register

A flexible, high performance

solution for programmable motion

requiring high speed

registration features |

Communication option modules

|

SM-CANopen

CANopen interface supports

various profiles including several

drive profiles |

|

SM-DeviceNet

SM-DeviceNET option module |

|

SM-EtherCAT

Slave/follower option module, for

high performance servo applications |

|

SM-Ethernet

supports Ethernet/IP and Modbus

TCP/IP and can generate emails.

Provides high speed drive access,

global connectivity and integration

with IT network technologies |

|

SM-Interbus

Interbus interface option module |

|

SM-PROFIBUS-DP

Slave/follower option module |

|

SM-PROFINET

PROFINET is an Ethernet based

industrial network protocol adapting

Ethernet hardware and protocols |

Input and

Output Option Modules

|

CTNet IO

Flexible I/O system for

remote connectivity with Control

Techniques’ SM-Applications Plus

and SM-Register option modules |

|

SM IO 24V

Protected

Overvoltage protected I/O

module |

|

SM-IO 120V

Module that provides digital

I/O rated to 120Vac |

|

SM-IO 32

Extended digital I/O, adding

32 digital high speed

bi-directional I/O points to the

drive |

|

SM-IO Lite

Extended I/O interface with

reduced functionality |

|

SM-IO PELV

NAMUR standard I/O interface

with high speed I/O |

|

SM-IO Plus

Extended I/O interface to

increase the number of I/O

points on a drive |

|

SM-IO Timer

Extended I/O option module

with real time clock |

Feedback

Option Modules

|

SM-Encoder

Output Plus

Incremental encoder input and

output option module that

enables connection with external

motion controllers |

|

SM-Encoder

Plus

Incremental encoder input

option module |

|

SM-Universal

Encoder Plus

Additional combined encoder

input and output interface

supporting Incremental, SinCos,

HIPERFACE, EnDAT and SSI

encoders |

External

Field Control

Field Regulator

Optional FXMP25 external field controller for field

currents up to 25A

Power Accessories

Remote I/O

CTNet I/O

Flexible I/O system for remote connectivity using Control

Techniques' CTNet Drive-to-drive network

Software

-

Control Techniques Windows-based

software packages connect using Ethernet, CTNet,

Serial or USB connections.

Ethernet communications allow the

drives to be accessed remotely, anywhere in the

world.

Control Techniques' software suite makes it easy to access

the complete feature set of our drives. These tools provide quick

setup of the drive, optimize tuning, configuration back-up, programmable

control and communications link set up.

-

CTSoft - Drive configuration

-

CTScope - Software oscilloscope

-

SyPTLite - Ladder program editor

-

SyPTPro - Full automation system programming tool

-

CTOPCServer - OPC compliant server for interfacing with

Control Techniques' drives

The Software tools communicate using Ethernet, CTNet,

Serial or USB connections. Ethernet allows the software tools to easily

use the internet infrastructure allowing Control Techniques drives to be

accessed remotely, from virtually anywhere around the world.

CTSoft

CTSoft is a configuration tool for commissioning, optimizing

and monitoring Control Techniques drives. It allows you to:

-

Easily configure the drive using wizards

-

Read, save and load drive configuration settings

-

Manage the drive's smartcard data

-

Monitor drive parameters and status

-

Visualize and modify the configuration with live animated

diagrams

CTSoft is free of charge and can be obtained by clicking the

download tab on this page.

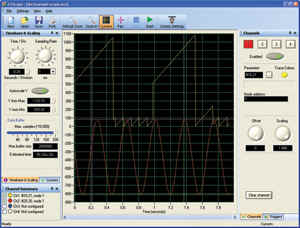

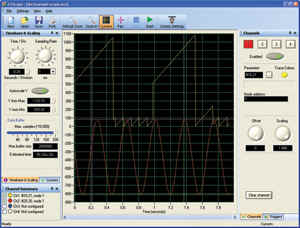

CTScope

CTScope is a full featured software oscilloscope for viewing

and analyzing changing values within the drive. The time base can be

set to give high speed capture for tuning or intermittent capture for longer

term trends. The interface is based on a traditional oscilloscope,

making it familiar to engineers across the globe.

CTScope is free of charge and can be obtained by clicking the

download tab on this page.

SyPTLite

SyPTLite is an easy to use ladder logic program editor,

suitable for simple drive applications. SyPTLite is ideal for controlling

basic logic and sequencing onboard PLC and with SM-Applications Lite V2 solution

module.

SyPTLite is free of charge and can be obtained by

clicking the download tab on this page.

SyPTPro

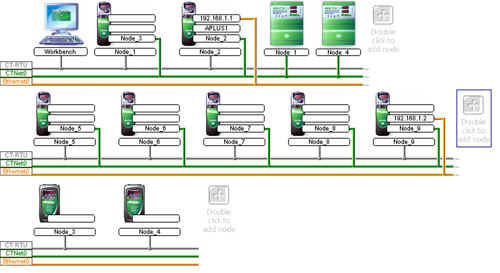

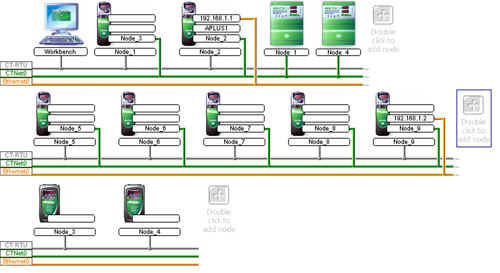

SyPTPro is a full featured automation development environment

that can be used for creating solutions to single or multiple drive

applications. The programming environment fully supports three industry

standard programming languages: Function Block, Ladder and Structured Text.

Motion is configured using PLCopen function blocks that support a master and

slave axis configuration.

SyPTPro is also used to configure CTNet, a high speed

drive-to-drive network that links together multiple drives, SCADA, operator

panels and I/O to form an intelligent networked system.

CTOPCServer

CTOPCServer is an OPC compliant server that allows PCs to

communicate with Control Techniques' drives. The server supports

communication using Ethernet, CTNet, Serial RS485 and USB. OPC is a

standard interface on SCADA packages and is widely supported within Microsoft

products. The server is supplied free of charge and can be obtained by

clicking the download tab on this page.

Software Available

-

Control Techniques Windows-based

software packages connect using Ethernet, CTNet,

Serial or USB connections.

Ethernet communications allow

the drives to be accessed remotely, anywhere in

the world.

Commissioning and monitoring

software

|

CTSoft -

Drive configuration tool for Control

Techniques drives CTSoft

is a drive configuration tool for

commissioning, optimizing and

monitoring Control Techniques drives |

|

CTScope -

Real-time software oscilloscope

CTScope is a real-time full featured

software oscilloscope for viewing

and analyzing changing values within

the drive |

Automation and motion

programming software

|

SyPTLite - Fast user

program editor for Control

Techniques drives

SYPTLite is a ladder diagram editor

allowing users to develop simple

programs for Control Techniques

drives and option modules |

|

SyPTPro - System

programming toolkit for drive

automation systems

SyPTPro provides a full featured

programming environment for PLC and

motion control onboard Control

Techniques AC, DC and servo drives |

Connectivity Software

|

CTOPCServer - OPC

compliant server

CTOPCServer is an OPC compliant

server for interfacing your own PC

software with Control Techniques |

HMI Software

|

CTVue HMI

Software Control

Techniques CTVue human interface

software tool enables the operator

to easily configure drive-related

control variables. |

The software packages connect using Ethernet, CTNet,

Serial or USB connections. Ethernet communications allow the drives to be

accessed remotely, anywhere in the world.

|